Advantage:

- Use the whole welding frame structure and vibration aging treatment. The machine has good rigidity, high precision, and good precision retention.

- Use a three-point supporting axle rolling guide rail. The upper tool rests and moves gaplessly in the rolling guide rail. Rotating the hand wheel can adjust the service life of the blade.

- The movable blade support and four-legged long blade are provided for easy adjustment of blade gap uniformity, improve shear quality and prolong blade service life.

- Use a tandem cylinder synchronization system. The machine is forced uniformly. Adjusting the flow of the tandem cylinder makes it very convenient to adjust the shear angle, which can meet the needs of different shear plate thicknesses.

- Use a motorized rear stopper device and electronic counter. It is convenient to adjust the position of the rear stopper.

—————————————————————————————————————————————————————————————————————————————————————————

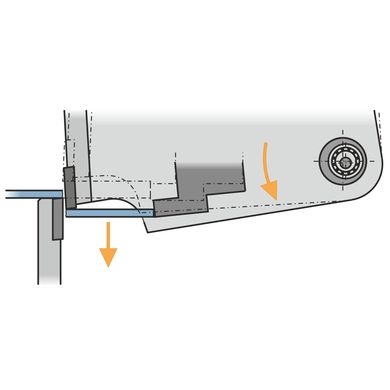

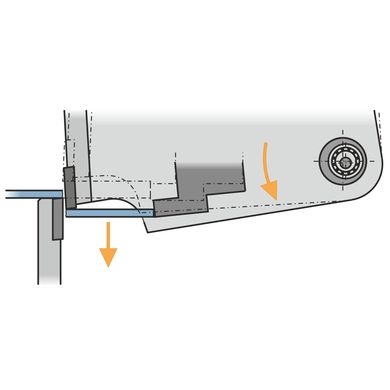

The swing-beam shearing machine usually adopts inclined blade shearing. It has been widely used because of its simple structure, low failure rate, high shearing efficiency, and no distortion and warping after cutting. In the shearing process, as the tool rest does rotary movement, the angle and shearing gap of the swing-type shear will change.

The machine is a steel-welding structure. Hydraulic transmission, vibration to eliminate stress, and it has high strength and good rigidity. Hydraulic swing-type shearing machines do downward shearing movement, and nitrogen cylinder return by using the main cylinder (fixed on the wall panel). So simplified, the hydraulic system operates more stably—the upper tool rest of the swing-type shearing machine swings around a fixed axis in the shearing process. Through leverage, the fulcrum has little force, which can improve the shearing blade and machine life. The whole machine is in a compact structure and can electrodeless adjust the stroke of the upper tool rest, significantly improving the working efficiency.

Advantage:

- The shearing machine, to obtain a high-quality workpiece, should be able to ensure the straightness and parallelism of the shear surface of the sheet after cutting and minimize plate distortion. The upper blade is fixed on the tool rest, and the lower is specified on the working table. Material supporting ball is set on the operating table, so the sheet material will not be scratched when sliding on it. The rear stopper is used for plate positioning, and the motor adjusts the position. The press cylinder compresses the sheet to prevent it from moving during shearing. The guardrail is a safety device to prevent accidents at work. The return usually depends on nitrogen, which is fast and has little impact.

The difference between Guillotine and Swing-beam shear:

1. Different structural forms: Guillotine cutting tool and the table between the translational structure, while the swing beam shear adopts a rotary structure.

2. Cutting method: Guillotine cutting method is by moving the cutting blade up and down to cut, while the swing beam shear is through the rotation of the tool to cut.

3. Scope of application: Guillotine is suitable for thicker metal plates, while the swing beam shear is suitable for thinner metal plates.

4. Cutting precision: Guillotine cutting precision is higher, while the swing beam shear cutting precision is relatively low.

5. Different prices: the Guillotine price is higher, and the price of swing-beam shearing machine is relatively low.